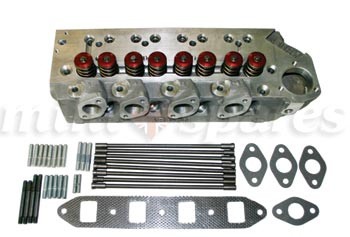

The combustion chambers are left in a basic shape only with a nominal 16.4cc which allows enough metal for those with the latest advanced ideas of shape to apply them and create the correct compression ratios for the desired use.

Valve and seat material specification allows use of unleaded fuel. Thoroughly clean the cylinder head before final assembly. Check that the small circlip is in the correct position in the valve guide at a point where the guide protrudes through the cylinder head beneath the valve seat. Place the valve spring seat over the guide. Fit valves using anti scuffing paste, fit rubber seal to stem valve.

The head should be fitted using cylinder head gasket C-AHT188 and ensure there are no burrs at the base of the head studs. The cylinder head is taller than original ‘A’ series castings and depending on how much material is machined off the face of the head to get required compression ratios certain modifications will have to be made.

- 4 longer studs 51K282 must be used on the inlet side, an alternative to this is the latest longer mini stud TAM1617.

- Rear block studs might not be long enough but 51K281 stud can be used 6 3/16” long with 5/8” block thread and 7/8” top thread.

- Standard push rods will not be long enough so the following alternatives are available.

- Machine rocker posts, original sintered are shorter than the steel type used on hi-lift rockers.

- Use longer adjusting screws C-AEA692 (will not fit C-AHT438).

- If possible get carbon fibre push rods made approximately 0.220” longer. Or adjustable tubular type from MED 01162461641.

- Old 1500cc Leyland Rover B Series push rods 11G241 are slightly longer but need machining to fit though head.

- Ford 105E Anglia cam followers/Push rods and modify,

If the heater is not being used, fit blanking plate 2A180 to water take off at rear of the head. Use standard water elbow and gasket.

Fit the high lift competition rocker assembly either C-AHT436 which utilises the latest forged arms fitted with bushes or the roller tipped variety – C-AHT446 or the fully roller rockered hi-lift set C-AHT438 which has roller bearings on a special rocker shaft.

Alternatively the standard forged rocker gear with lower sintered posts can be fitted with slight power loss. Forged rockers may require machining on the sides to ensure they are central over the valve stems. (Check all rocker gear) and if using valve rocker spacers they should have a minimum gap of 0.002”.

Check that all valve train is functioning correctly and valves not hitting pistons on modified blocks. 10mm spark plugs are required for this head. C8E for road use and C9E for Race. Amal carburettor kit C-AJJ4083m is complete with four carbs, inlet manifolds and linkage is suitable for this cylinder head. Exhaust manifold C-AHT343 will be required. If fitting twin webers use C-AHT507 short inlet manifolds or C-AHT508 long inlet manifolds.

Cooper “S” con rods and crankshaft must be used (1.625” big end journal) Owing to the head having a non standard valve sequence, number two and four connecting rods may foul the camshaft. To overcome this, top edge of connecting rod or bolt should be chamfered as per Fig 1 to produce adequate clearance. Valve clearances can not be set as per std five port sequence. Turn engine over until one pair of valves are rocking, then adjust it’s opposite pair(with cylinder four pair rocking, adjust cylinder one pair and vice versa, and same for two and three)

For Fitting we recommend you try ex ST mechanic Bill Richards Racing 01233 624336.

If you require electronic induction system as well as fitting try M.B.E 01522 522244

The above two companies plus MED Engineering 0116246 1641 and Swiftune 01233 850843 are also recommended Mini Spares own electronic fuel injection package is now discontinued.

When using a new unmachined cylinder block, the block face can be machined to within 0.25”(0.635mm) of the piston crown at T.D.C. This will give approximately 12.5:1 on a 1293cc engine with 13cc chamber.

If the cylinder block being used has undergone machining to bring the piston to within 0.10”(0.254mm) of the block face, machining the piston crown is necessary.

Providing MiniSpares Mega pistons are used 0.015”(0.381mm) can be removed with safety by machining the total of the piston crown. Alternatively, machine the piston using a cutter of 1.625”(41.275mm) with a radius of 1/16” (1.6mm)