During a trip in 1984/5 to Ivra the Mini and Innocenti parts manufacturer and stockist in Milan I noticed some strange shaped rubber suspension cones that transpired to have been used on the heavier Innocenti 120 mini, produced from 1978 that was fitted with the 1275cc British Leyland power plant producing 74BHP. The Mini 90/120 cars production had finished by 1982 and having never seen this shape cone before I was intrigued enough to buy 100 for trial and found positive results and great feedback from rally drivers and performance mini owners, so I purchased the remaining stock of about 800 in January 1986 which lasted until 1993. It transpired Dunlop developed this shape to stop body roll on this taller heavier hatchback model to help change the ride over the cobbled or undulating Italian streets.

I contacted Dunlop about these special rubber cones with patent number 620734 but they were very reluctant to offer any help as they held the patents with BL/Rover, but having had 5000 of the Cooper S Wheels 21A1286 remade in 1980 by Dunlop I managed to find out from my contacts the bad news that the tooling had been scrapped and they had no interest in resurrecting the product (the same old sad story would unfold similar to the hydrolastic units).

Between 1978 and 1981 Dunlop USA spent $102 million on modernising its European tyre business.] The British workforce was cut from 13,000 to 7,000 with departments being closed down, hence the probable loss of the hydrolastic tooling . It was after a disastrous merger with Pirelli in 1971 until 1981 that indirectly lead to the whole Dunlop group of companies being sold to BTR in 1985. BTR who also made the many rubber body seals for the mini gradually split them up and sold them off, with the Systems and Components division transferring to Trelleborg AB at the end of the 1990's, but a management buyout in 2007 allowed the company to modernise, culminating in the current building which was completed in 2014.

I had always been trying to get Alex Moulton to help in getting the competition hydrolastic units remade early 1980's and standard units again especially after Rover made them obsolete when stocks run out in 1989 but he had no interest at all saying they were too difficult to manufacture and that he would not part with any drawings or any help in the manufacturing process at any cost. Alex Moulton also reflected on the cost and scrap rate encountered, but my contacts in Rover etc were unaware of any major production problems. Unbeknown to me Dunlop had discontinued making displacers in 1978 and must have suffered any losses themselves as I never had any warning the huge testing equipment and tooling would be scrapped and as sales were quite low the "all time buy" by Rover allowed them to carry on selling them at £27 to Mini Spares and other main dealers for over 10 years without any increase. Rover all time buys were usually 10 years worth of stock holding where they are obliged to keep replacement parts and the tooling was often scrapped (a bad policy for classic car owners but saved companies large amounts of money on storage of machinery or tooling and their replenishment costs which made good business sense at the time). In 1994 I bought my last 200 displacers sourced by Tony Fitchet who was Rovers scrap and clearance contractor at £52 each. I paid a lot more for odd new units that I could subsequently find afterwards.

Having spoken to Alex on quite a few occasions about hydrolastic units I also enquired about the Innocenti suspension cones I had discovered wondering if with his contacts he could get them made. (Plus the standard type of course as the only source available were Rovers made by Dunlop which were expensive.)

Big mistake! As he hated anything being uprated or stiffened but I debated the fact that many car manufactures were now fitting anti roll bars and stiffer suspensions for better handling. (BMW).

Later interviews and articles regarding Alex Moulton also showed or indicated his complete dislike for the New Mini with its firm suspension.

Mini guru and good friend Keith Calver was also intrigued by the Innocenti cone springs shape and its handling ability so he took over the research and his consultations with Moulton also produced the same conclusions I had experienced, except Keith Calver probably started the birth of Moulton's taller softer unit using our ideas and design of the top plate with an integral thread for fitting rather than the original welded on nut, but we did not particularly like or want a softer unit as it was similar to prototype coil springs which I had tried where you get a wishy-washy drive losing the minis sharp handling, especially on B roads or any UK road these days.

Keith and I both proceeded to put a lot of time into research on rubber products and entered a science very new to us both. By 1993 Keith had already put a lot of his time into the cone spring research and development whereas mine had gone into suspension and tie bar bushes getting the correct shore hardness, plus the hysteresis of rubber where it changes shape after heating up or during use.

Luckily Mini Spares sponsored a Mini 7 Miglia racer who worked for a Formula one team who was a good friend of Keith Calver's, he was able to get the cones tested on their special equipment rigs and also gave us the name of a rubber specialist company they had used. Special mixes of rubber compounds were used and with help by another successful Mini Miglia champion driver Peter Baldwin we were also able to produce and test the perfect rubber compounds culminating to give the perfect cone spring for racing and by January 1994 Mini Spares own versions of the cone springs were available for sale.

The yellow dot C-STR688 which helped cut down lap times and help win races. Over an average Miglia race season of up to 15 races our new cones springs might only need changing 2-3 times whereas the original standard FAM3968 from Rover would not even last more than a few laps in a Miglia race car, this was the appliance of science, in action.

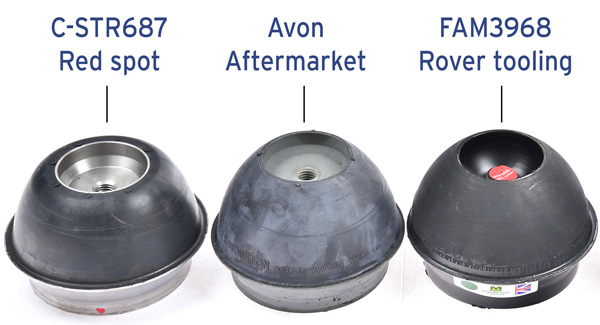

Mini Spares own C-STR687 road use performance cone springs marked with a red dot gives such a good ride using them on the front by stopping excess body roll with a more supple and compliant ride ,they are even favored over the standard cone spring by many enthusiast mini owners but because of the design difference Hilo's must be fitted, but with the correct combination of dampers you have the complete suspension package. The original Innocenti cones were the same height as the genuine FAM3968 but our C-STR687 and 688 are shorter in height at about 85mm new, but the different shape and rubber compound give them an initial higher ride height.

What holds Mini Spares Centre apart from many is our parts knowledge, transparency and truthful descriptions of describing parts without any deception or tongue twisting. Owners of minis usually work out in time which company is the best and the most honest to deal with.

Are you confused about cone springs?

From the Mini's production in 1959 until 2000 every mini and factory aftersales cone spring was manufactured only by Dunlop, under license to BMC through to British Leyland and until 2005 when Rover collapsed.

So, if you want to keep your car to its original and correct specification your old or new cone spring can be identified by the following characteristics.

A) Original Rover production--The name Dunlop and Moulton imprinted into the rubber with patent number 763432 and a welded hexagonal nut on the metal top plate for fitting.

B) Using the same original Rover tooling but Current production-it has only the patent number 763432 plus identification M part sticker.

The Dunlop name was deleted from this original UK Dunlop tooling as it is a trademarked name and the Moulton name is also deleted to save confusion but M PARTS Ltd is etched into the rubber.

This still has the original welded hexagonal nut on the metal top plate and both are the same correct height of 93mm when new.

C) If it has Alex Moulton or Avon VMS imprinted into the rubber these are aftermarket cones UK made by Avon VMS who are owned by South Korean automotive supplier Dongah Tyre and Rubber- these are not the original or genuine item and were never fitted to any production mini or factory aftersales unit. This type also has the threaded top plate as designed by Keith Calver and similar to our C-STR687/688 but the Mini Spares type are only marked with red or yellow identification dots.

Any other cone springs we have seen or been involved with to date were imports and should be avoided as they were very poor quality and have a large failure rate as they were made without the technical knowledge required, These seem to have now disappeared from the market as they caused the sellers and mini owners grief.