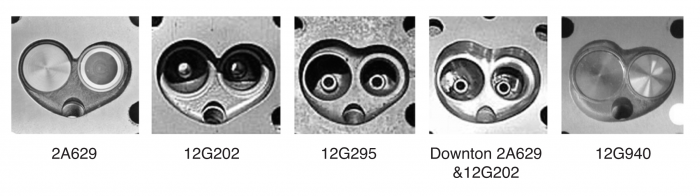

| Casting number |

Inlet |

Exhaust |

CC |

Normal Application |

Notes |

| 2A628-No such casting.———— 21086 is good |

1.0625” |

1.000” |

24.5cc |

Austin A30 & |

Note 1 |

|

26.99mm |

25.4mm |

|

Morris Minor series 2(803cc) |

| 2A629 |

1.0625” |

1.000” |

24.5cc |

850, 998cc Mini 948cc inline |

Note 2 |

|

26.99mm |

25.4mm |

|

|

| 12A1456 |

1.0625” |

1.000” |

24.5cc |

848, 998cc Mini Sprite/Midget 948cc |

Note 3 |

|

26.99mm |

25.4mm |

|

|

| 2A609 Authi |

1.0625? |

1.00? |

24.5cc |

Authi Mini 850cc & 998cc |

Note 4 |

|

26.99mm |

25.4mm |

|

|

| CAM4810 |

1.0625” |

1.000” |

25.5cc |

998 Metro &Mini A plus, 1980 on and 89 on lead free- |

Note 5 |

|

26.99mm |

25.4mm |

|

|

| CAM4004 |

1.0625? |

1 |

25.4cc |

998cc air injection ports |

Note 6 |

|

26.99mm |

25.4mm |

|

|

| 12A185 |

1.156” |

1.000” |

24.6cc & 26.1cc |

997 Cooper Sprite/Midget early 9 stud, |

Note 7 |

|

29.36mm |

25.4mm |

|

|

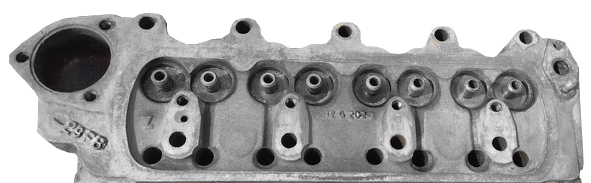

| 12G202 |

1.156” |

1.000” |

26.1cc |

997 Cooper, all 1100cc square inlet ports |

Note 8 |

|

29.36mm |

25.4mm |

|

|

| 12G201 Authi |

1.156? |

1.00? |

24.7cc |

innocenti/Authi ADO16 1098cc |

Note 9 |

|

29.36mm |

25.4mm |

|

|

| 12G206 |

1.156” |

1.000” |

28.4cc |

few early 998 Cooper & Sprite 10CG engine |

Note 10 |

|

29.36mm |

25.4mm |

|

|

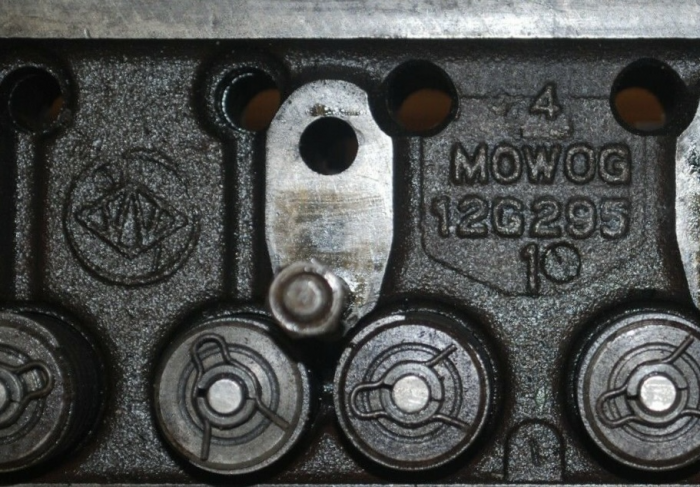

| 12G295 |

1.218” |

1.000” |

28.3cc |

998 Cooper, MG1100 locating ring insets |

Note 11 |

|

30.93mm |

25.4mm |

|

|

| 12A185/AEA626 |

1.401” |

1.22” |

21.4cc |

MKI 1071 Cooper S 1963 |

Note 12 |

|

35.6mm |

31mm |

|

|

| AEG305 |

1.401” |

1.22? |

21.4cc |

1071 early Formula junior |

Note 13 |

|

35.6mm |

31mm |

|

|

| AEG163 |

1.401” |

1.22” |

21.4cc |

MKI//2 1275cc Cooper ‘S’ |

Note 14 |

|

35.6mm |

31mm |

|

|

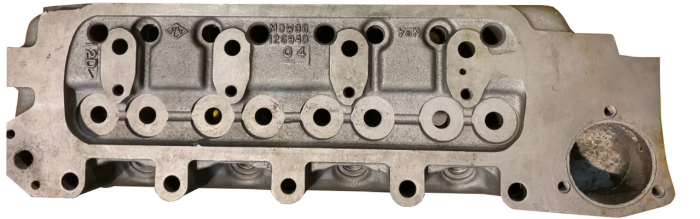

| 12G940 |

1.3125” |

1.156” |

21.4cc |

1300, 1275GT & all A+ & Turbo |

Note 15 |

|

33.3mm |

29.2mm |

|

|

| 2G93 NMQ Authi Spain |

33.3mm |

29.2 |

21.4cc |

1275 |

Note 16 |

|

35.6mm |

|

|

|

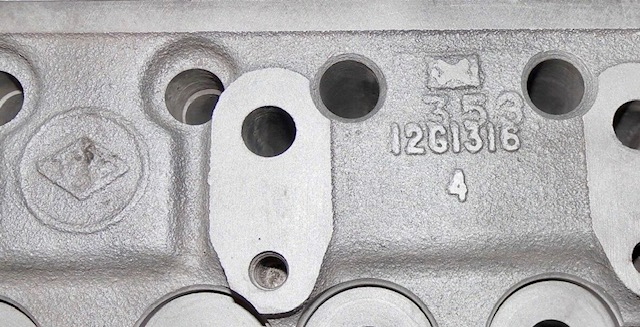

| 12G1316 |

1.3125? |

1.156? |

21.4cc |

Air injection ports, 1275cc |

Note 17 |

|

33.3mm |

29.2mm |

|

|

| 12G1805 |

1.401” |

1.156” |

21.4cc |

MG1300, 1300GT, Cooper ‘S’ MK3 |

Note 18 |

|

35.6mm |

29.2mm |

|

|

| 12G940 |

1.401” |

1.156” |

21.4cc |

A Plus MG Metro / Vanden Plas HC 9 stud only |

Note 19 |

|

35.6mm |

29.2mm |

|

|

| 12G940B |

1.3125? |

1.156? |

21.4cc |

Mini 1991 on HIF38 and SPI |

Note 20 |

|

33.3mm |

29.2mm |

|

|

| LDF105800 |

1.3125” |

1.156” |

21.4cc |

Multipoint injection |

Note 21 |

|

33.3mm |

29.2mm |

|

|

| C-AHT347 |

1.406? |

1.161? |

21.4cc |

Mini Spares Alloy Head |

Note 22 |

|

35.7mm |

29.5mm |

|

|

| CC = Original Combustion Chamber Size |

|

|

|

|

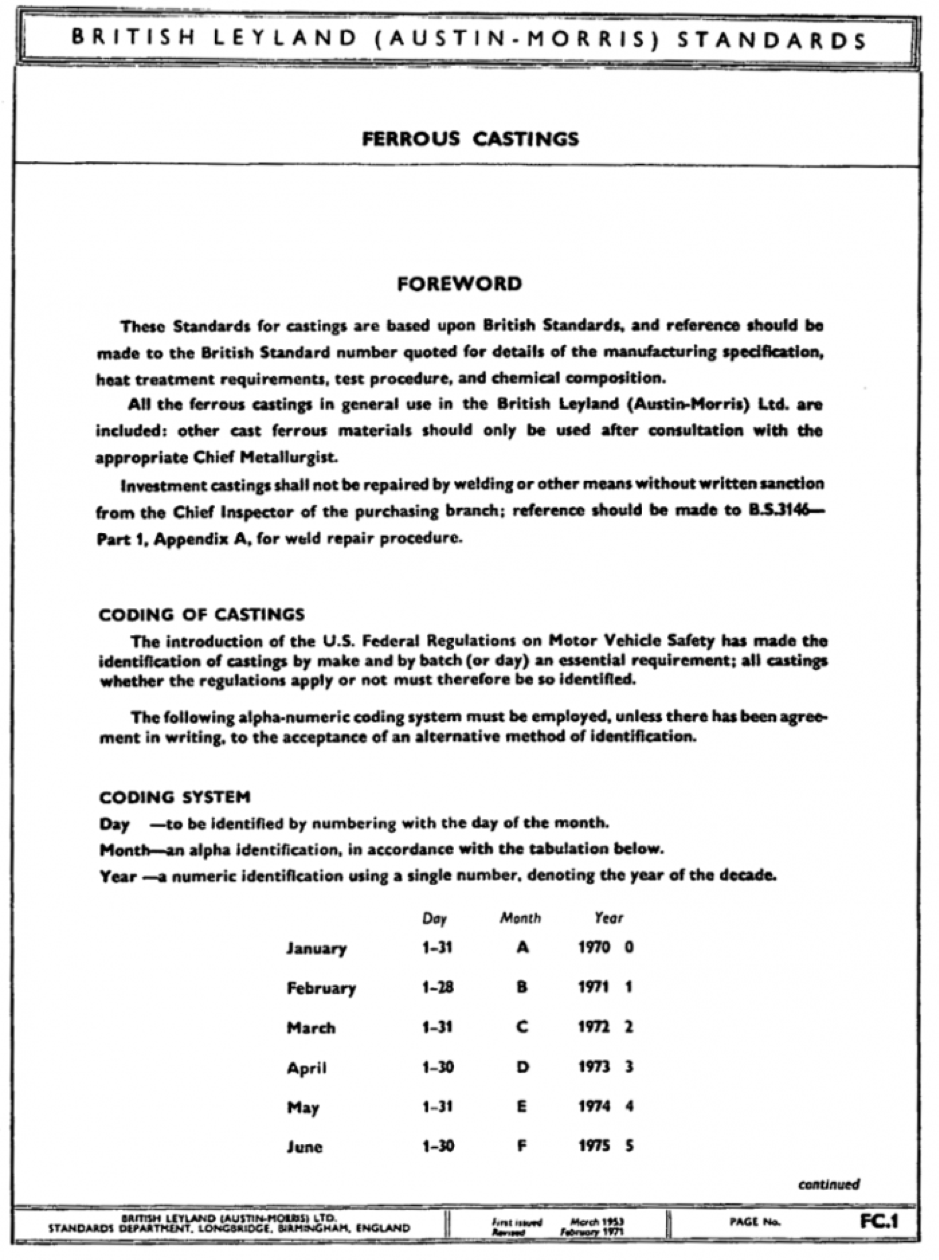

So many misleading articles and claims of rarity seem to crop up about the A series heads that I have added my findings, starting from when I first began unbolting and changing cylinder heads at the Austin/Morris dealership where I started work in 1963 the same year William Morris (Lord Nuffield) died, who was the founder of Morris Motor co, Morris Garages leaving his legacy of MG, Morris and Wolseley with the name MOWOG on parts and packaging. From 1966-68 the assembly lines went through traumas with Leyland taking over in January 1968 with top personal changes causing Austin and Morris to eventually alienate each other allowing unscheduled parts and oddities to be fitted to get vehicles built for sale. Sorry this article became a thesis but read it all to understand the differences and changes as most of this is from memory or notes from years ago plus what I know or have found out to date.

Since the manufacture of the first A series heads was nearly 70 years ago not many early engines or owners are original and many head swops, refacing or valve changes along with other irregularities have been found but the following shows the original characteristics.

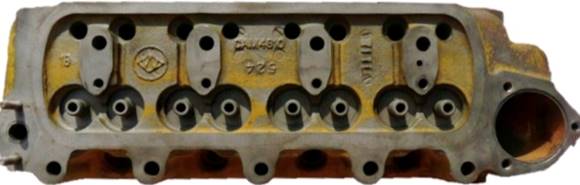

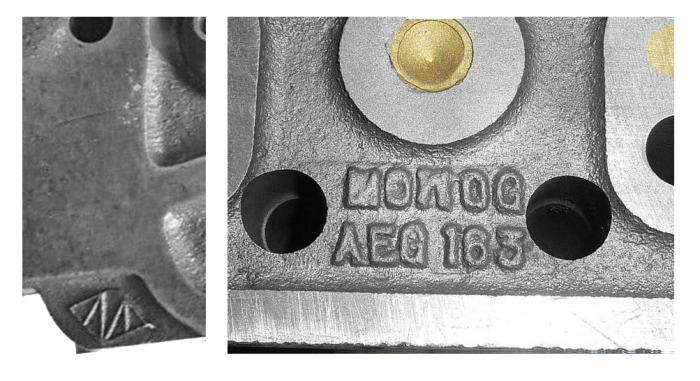

Cylinder heads with MOWOG cast in them originated from Morris Engines, part of Morris Garages, Court House Green, Coventry where an original Special Tuning Dept originated in 1957 as Morris Engines were supplying power units for the MG/Sprite builds at Abingdon, where the famously known BMC ST Dept Abingdon as we knew it, originated from in the 60’s. Eddie Mayer was Morris Engines brains behind getting increased power and changes to the engines design and with Downton’s Daniel Richmond getting involved with him on cylinder head flow designs to the original 1943 patented Harry Weslake’s head designs, there was no holding back major development. Daniel Richmond then worked closely with Issigonis at the Longbridge site from the early 1960’s and as far as we know was responsible for the 1275cc 12G940 casting and port shapes which were similar design to the 12G295 although for totally different fitment uses. Morris garages had owned Wellingborough Foundry from 1947 and were acclaimed as being one of the finest head casting companies in the UK and most of their heads had MOWOG cast on them along with Wellingborough Foundry’s own casting mark, a Capital W in a rhombus shaped triangle. Wellingborough Foundry closed about 1981 and most of its work transferred to Beans Industries @ Tipton who Longbridge used. Beans Industries casting mark was a capital B leaning to to the right in a circle or the letters BIL. Other Longbridge heads also came from C&B Smith Ltd (CBS in a circle) who by 1965 became GKN Forgings and Castings which during early 1980’s then became part of Birmid Qualcast group. Also heads were cast at West Yorkshire Foundry, Leeds. See end of article for foundries and brief history.

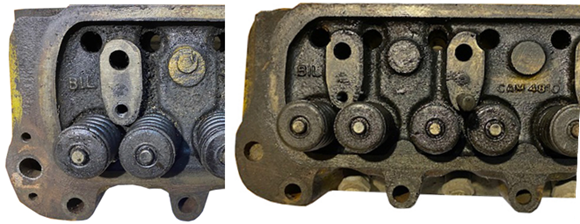

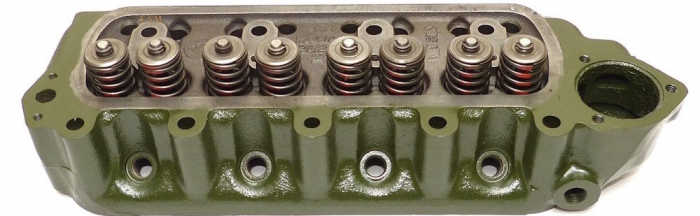

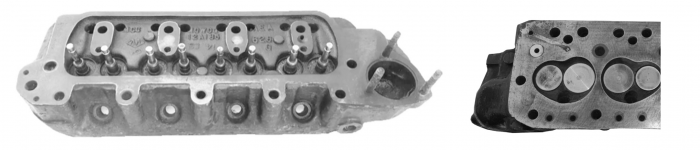

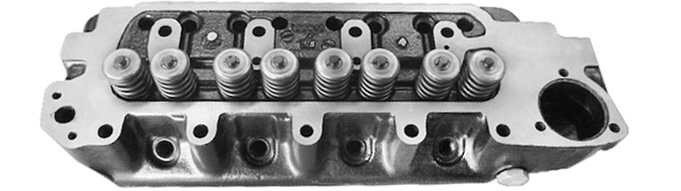

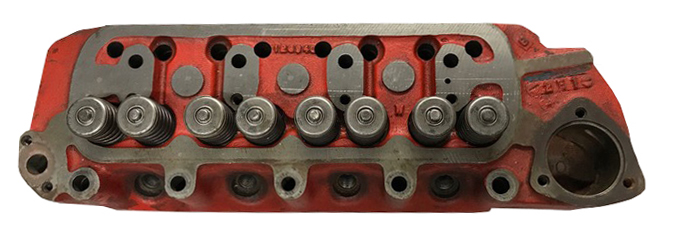

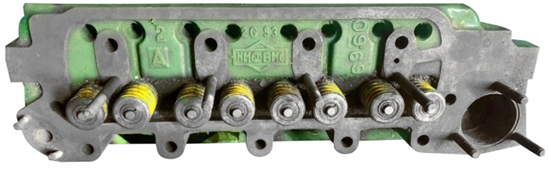

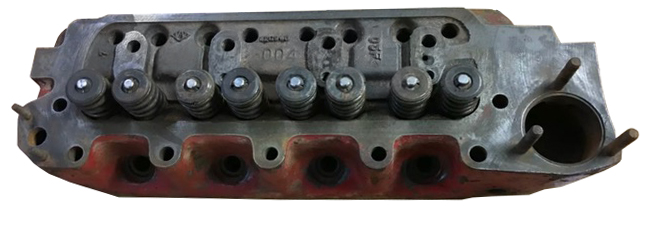

Large bore heads are a classification for all Cooper S variants, 970, 1071 and every 1275cc which all started with 2.780? (70.6mm) piston bore size. Small bore heads are 803cc, 850cc, 948cc, 997cc, 998cc,1098cc with any original bore size up to 2.54?(64.57mm). All small bore only ever had old imperial 1”wide exhaust valves. (25.4mm). Basically, never fit a small bore head to a large bore engine and fitting a large bore head to a Small bore engine is not always advisable for road use and requires a lot of work, knowledge and modifications. Small bore heads had the rocker oil feed plug on the bottom of the head whereas large bore had the rocker oil feed plug at the top. Originally they used a brass plug as shown on the red head below but on A plus used a rivet and a very large rivet from 1991 on as shown on extreme right

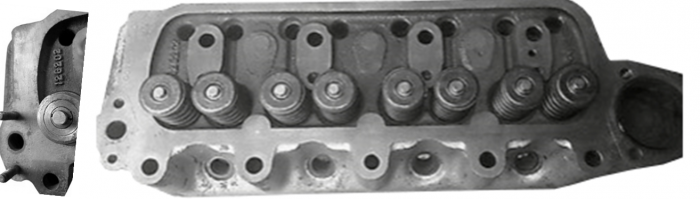

A plus small bore on left with oil gallery rivet for rockers feed on bottom of head and then large bore heads with oil gallery on the top of the head using plug and rivets

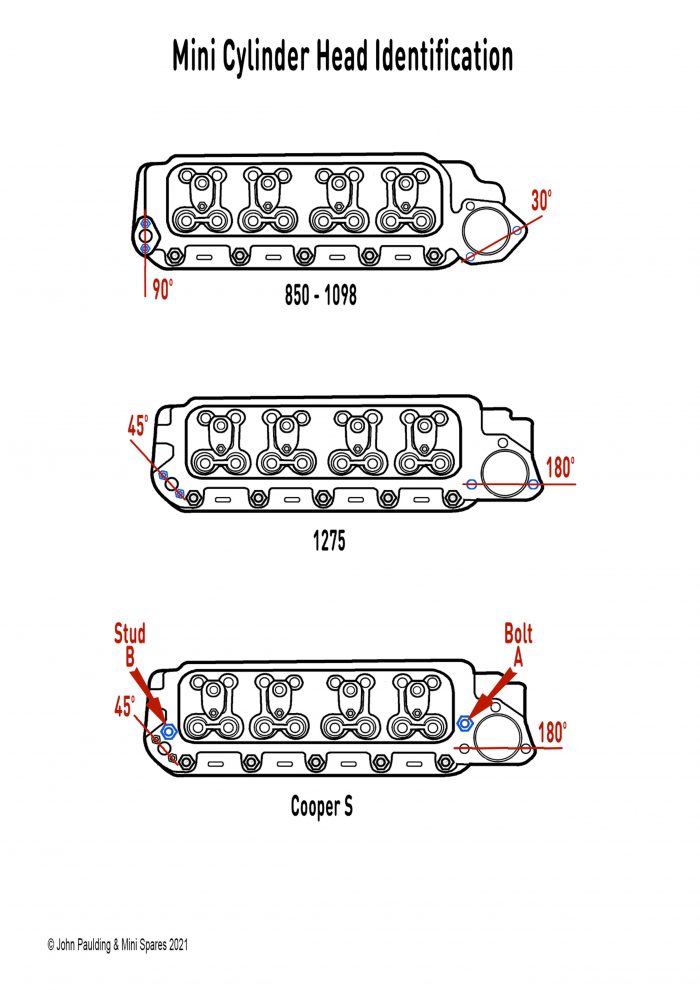

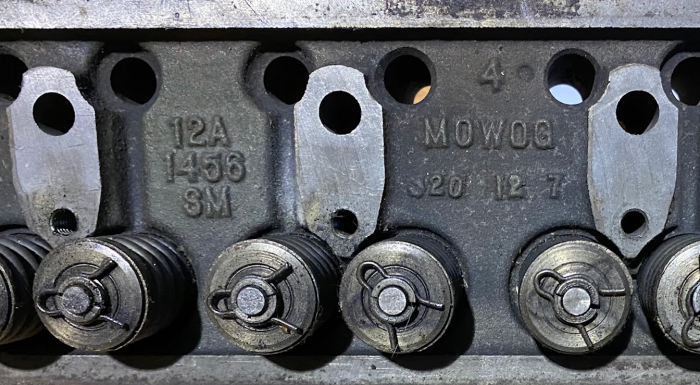

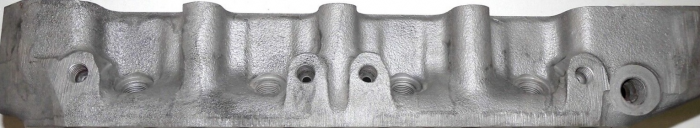

The casting numbers are viewed by looking on the top of the head with the spark plug holes in front of you, with a few numbers upside down or sideways. The last of 12G202,12A1456.12G940 heads made from the very late 1970’s could have the number cast at the back of the thermostat. The 12G940B started with SPI from 1991 and LDF105800 for MPI from 1996 have the numbers cast on the end of the head by the exhaust manifold tube and the old heater valve location. All numbering starts from number one piston bore the thermostat end -1st to 4th rocker pedestal, 1st to 8th valve and 1st to 8th push rod hole. The easiest way to tell the difference between small bore and large bore heads is by looking at the thermostat stud positions and the heater tap angles. All large bore, Cooper S and 12G940 have the 2 front thermostat studs level with front head studs whereas the small bore 850cc to 1098cc have only one stud at the front. Heater tap holes are at 90 degree angle on small bore heads and 45degrees angle on large bore heads.

At least 14 million A series heads were made with slight variations to fit Mini, Metro, all the range of 1100/1300, Allegro, Austin A30/A35/A40 Farina, Morris Minor, Austin Healey Sprite and MG Midget, Marina, Maestro, Ital Montego, using one of the following 803cc, 848cc, 948cc, 997cc, 998cc, 1098cc, 970cc, 1071cc and a majority being 1275cc. Every head in the last few years appears for sale fairly regular, so no head is particularly rare apart from very rare large bore 11 stud head AEG305, next the 12A185/AEA626 and then AEG163 S type heads. Prices for secondhand heads have risen as vendors try their luck. PS-although the Mini had special editions known as Sprites, namely 1983/4 with 998cc engine and 1992 with 1275 engine, we refer to Sprite/Midget as the 2 seater sports car from 1958-74 on our application list.

All castings are liable to have many core and reference markings, let alone rivet and screw head marks that are of no consequence or meaning to anybody now, but using the reference chart the following are the main casting numbers characteristics to look for. Small bore heads with a recessed or sculptured manifold face were the earliest type with clips on the valve collets which had deep square cut collet grooves. The Cooper S until fitment of 12G940 castings also had recessed or half sculptured backs, but every 12G940 produced from 1966 had a flat manifold face and some other head types were gradually phased in with flat manifold face from 1967 similar to all 12G940 castings. The valves with small single semi circular cotter grooves as fitted to all large bore were also gradually phased in by 1969 across most of the A series small bore range. The last generation of 12G202, 12A1456 and A Plus 12G940 had strengthening lugs behind the middle 3 of the front 5 head studs which can only be seen when rocker cover is off, this was a feature earlier heads did not have. Remember: All SMALL BORE had 25.4mm (1.00”) exhaust valves, All LARGE BORE, Cooper S Mk1/2 AEG163 had 1.22? (31mm) and all 12G940 heads had 1.156?(29mm)exhaust valves.

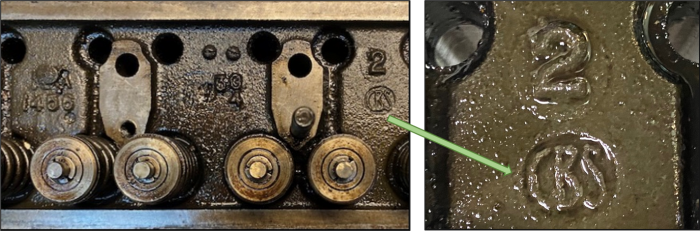

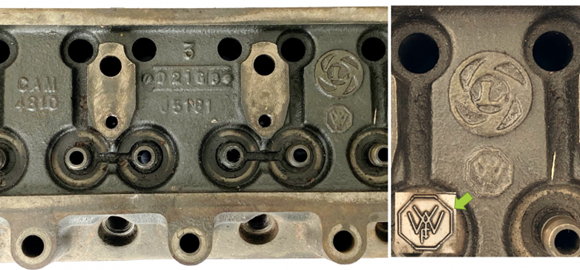

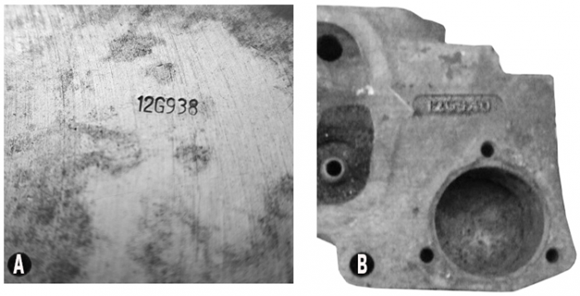

Note 1. THE MISREAD 2A628- 1.0625”inlet and round inlet port. To my knowledge 2A628 head never existed but was misread and started life in David Vizards Book, How to modify Your Mini in the 1970’s. Proof and correct castings number’s below.

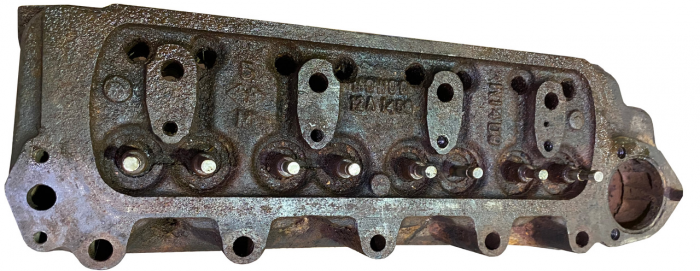

The first A series heads appeared in 1951 with the 803cc, Austin A30 and Morris Minor Series 2 in 1952, with no temp transmitter hole. (A) The first versions of this head pictured on the left only had 2A3/AF2/AS3 or 2AC/AF1/AB3 with none of the usual 2A629 casting numbers. AS3 was the code name for the new Austin A series engined A30 at Longbridge’s in the late 40’s way before the merger with Morris 1952 and made at the Longbridge North works. The 2A represented the engine number on the A30 whereas the engine numbers we are more familiar with start with an 8 for 850cc Mini and 9 as a prefix as on A35, Coopers etc. BMC stopped using the 2A prefix in 1952 leaving AF2/AS3 between 3&4 rocker posts as per middle photo (B) but added MOWOG above 2A629 between 2&3 rocker posts. MOWOG being for aligned to Morris and Cowley. It was in fact only ever a 2A629 but the casting numbers on the right hand photo (C) shows that if cast poorly or covered in oil it could easily have been misread as 2A628.

21086 is first of 2A629 design cast at Morris Engines for the early 803cc Morris Minor Series 2

Same 21086 head but with 2A629 from all upside down as Morris Engines 2nd generation

See Note 2 below for the main 2A629 history.

Note 2. 2A629- 1.0625?inlet and round inlet port, all with recessed manifold face, and only head without a temperature transmitter hole.

Read Note 1 for earlier history, but from 1953 948cc inline engines A35/A40 Morris Minor used this head except the 1962 on Sprite Mk2/midget MK1 which used a new 12A1456. The 2A629 was fitted to the Mini 1959 to 1968 but used a 12A408 thermostat housing to hold a temperature transmitter for the Mini Deluxe versions, plus Elf and Hornet which had a temperature gauge fitted in a 3 clock binnacle. Mini production stopped at Cowley in 1968.

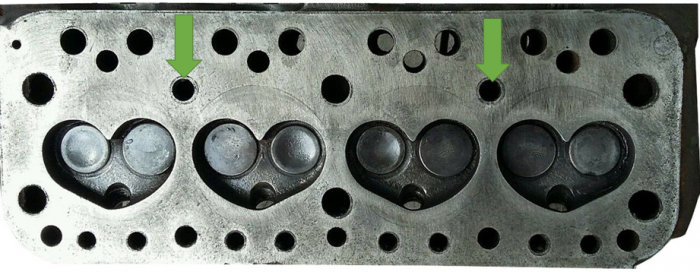

These are the 2 smaller waterway holes on early heads as the designers and technical staff were always looking to make improvements

MOWOG cast above 2A629 between 2&3 rocker posts, AF2/AS3 between 3&4 rocker posts. First head with 2A629 as described under 2A628 description. Longbridge head and the row of 5 waterways had smaller holes on 2 and 4.

Above has 2A629 upside down but can be correct way up

2A629 Casting number between 1&2 rocker posts MOWOG in between 2&3 rocker posts, No Wellingborough symbol. 2A629 upside down between 1&2 rocker posts and MOWOG correct way up between 2&3 rocker posts

All 2A629 had a recessed or sculptured manifold back face on. Early head casting from Wellingborough foundry

MOWOG over 2A629 between 2&3 rocker posts and with the W in a rhombus triangle upside down between 3&4 rocker posts from the Wellingborough Foundry as shown on the picture heading this article. I have also seen some without the Wellingborough symbol that have 2.8085? 71.336mm deck thickness when the std deck height was 2.75? 69.85mm. from Austin A30. The row of 5 waterways had smaller holes on 2 and 4

The most popular head fitted from 1959 on to Mini, Frogeye Sprite & Morris minor etc.948cc

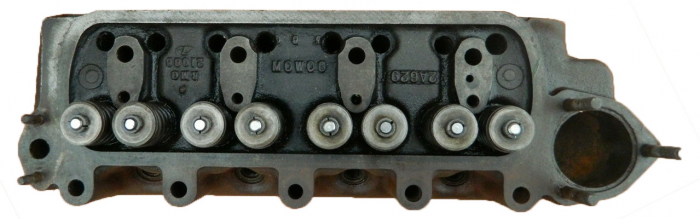

The next and last generation heads had 2A629 over SM between 3&4 rocker posts and MOWOG between 2&3 rocker posts, less all the other numbers. The most frequently available head fitting everything from Frogeye Sprite to Morris Minor and Mini to 1963 that i have noted. I have at least 10 of these and probably fitted from 1959 to1968 at least.

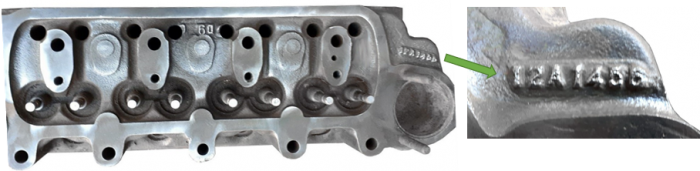

Note 3. 12A1456- 1.0625”inlet and round inlet port, with Temperature Transmitter hole,

Early type with recessed manifold face and no other markings, basically the same as 2A629 but with slightly changed waterways and a hole at front for temperature transmitter

12A1456 over SM between 3&4 rocker posts and MOWOG between 2&3 rocker posts. Early circlip cotters and valves with recessed manifold face. Like the one above Probably for MG/Sprite 948cc 1961-3 (16,000+models) that Morris Garages supplied to the Abingdon built cars, but maybe not from the Wellingborough foundry where some 2A629 were made, recessed manifold back face. Circlip type cotters.

MOWOG over 12A1456 between 2&3 rocker posts and Wellingborough motif between 3&4 rocker posts, Early valves with recessed manifold face MOWOG over 12A1456 between 2&3 rocker posts with no Wellingborough symbol, so maybe a Longbridge destined head with early valves and recessed manifold face

12A1456 with CBS insignia from the Wednesbury Wolverhampton foundry owned by GKN

12A1456 casting number between 3 and 4 rocker posts, flat manifold back face and late valves and cotters about 1969/70 on for 850/998 Mini and all 998 Clubman. Some have a CBS emblem in small circle between 1&2 rocker posts. The 12A part of the number is obliterated by a casting mark. C&B Smith (CBS) became part of GKN forging and castings in 1965 which in the early 1980’s then became Birmid qualcast. CBS name used late 60’s

(A) 12A1456 between 3&4 rocker posts and J5058 between 2&3 rocker posts (some look like J6058)with flat manifold back, later small collet valves. Some castings had good port shape and valve seat positions which were favoured by engine tuners for 1000cc Autocross regulations. Pictured below on left marked (B) Pictured above in the middle as 12A1456 cast sideways after 4th rocker post by 8th push rod hole, flat back manifold face, with extra 3 front centre head stud lug reinforcements from late1973. (C) On a later casting the number is upside down to the one shown and was moved closer to the push rod holes so only reads 12A14 or 12A145, often with a B by No1 valve but is not the Beans emblem, with extra 3 front centre head stud machined lug reinforcements from October 1973 to Mid 70’s head from Longbridge

W in rhombus triangle for Wellingborough foundry above thermostat housing late1970’s with raised machined lug reinforcements behind 3 central head studs

12A1456 between 2&3 rocker posts and the Wellingborough symbol moved behind thermostat housing close to where they originally stamped the first S heads. 3 front centre lug reinforcements and a flat manifold face

Pictured above 12A1456 number cast behind thermostat housing-with extra 3 front centre head stud lug reinforcements and no other markings, with a flat manifold back were the last type 1979/80, pre A plus

Note 4. 2A609 Authi Mini 1.0625? inlet and round port inlet

A) Similar to early 12A1456 with thermal transmitter hole and early recessed manifold face but later type small groove cotters and valves this was fitted to Authi 850/998cc minis from 1969/70 to circa 1975 made in Los Corrales De Beulna near Santander by NMQ until its closure. The BL insignia was probably used on the part number rather than NMG as per the 1275cc because Authi became 51% owned by BLMC in 1969. B) There was also an ALLOY head cast 2A609 by Barwell for Derrington with small bore valve centres and also one for large bore valve centres but with 11 bolt holes and 2A609 on both by 1st valve spring. Both had 1275 angle thermostats and 997 valves but larger valve sizes often put in such as 1.156? exhaust but only 998 cooper size inlets. I have seen a few in the UK (Calver ST on facebook) and in the USA a head can be viewed on Mini Mania website. I have only included this alloy head as it had a relevant part number to A series heads but had an unusual combustion chamber shape.

Derrington on left segment and Barwell on right above patent number

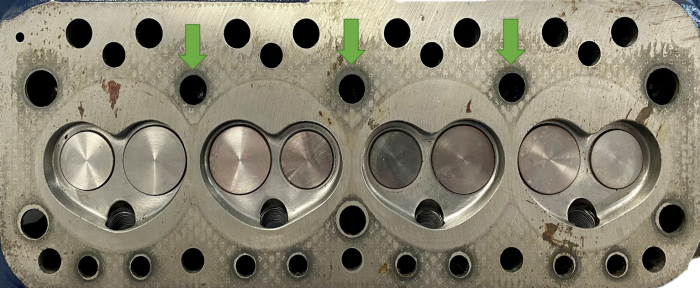

Note 5. CAM4810 A plus, 1.0625”inlet and round inlet port.

All the A plus 998cc heads had flat manifold face and later post 1981/2 had the extra machined lugs on the back of 3 front middle head studs. I believe all Beans or heads machined at Longbridge for the assembly line were yellow with smaller water jackets probably to stop valve seat cracking, although over heating never seemed a real problem. Introduced from 1980 at Longbridge, with Wellingborough Foundry closing in 1981 and their production transferred to Beans Industries at Tipton. Morris Engines at Courthouse Green then subsequently closing by 1982. Some early heads without the 3 front stud strengthening lugs were cast at West Yorkshire Foundry Leeds, of which some were green or black.

Three green arrows denote the smaller holes about .500? (1/2?) average whereas the larger holes are 0.625?(5/8?) average as per drawings in old British imperial size but do fluctuate.

Found on Allegro 1980-82, Metro 1980-90, Mini 1982-1992 . Valves with single collet groove were phased out by 1983. Later valves had 3 collet grooves and the collets had twin grooves with a 14 degree cone taper instead of the 10 degree taper as used on Pre A Plus single groove collets. The A Plus new spring caps have a raised ridge around the collet hole.

Last of the Wellingborough logos before its closure in 1981 between 3&4 rocker posts

Same head but different casting with Wellingborough logo between 3&4 rocker posts

CAM4810 between 2&3 rocker posts high under 4&5 push rod holes with W symbol between 3 and 4 rocker posts and no lugs on front stud posts was the last heads from Wellingborough Foundry 1980-1 mainly for the Metro with by pass hose blanked off.

CAM4810 between 3&4 rocker posts and the Leyland roundel Motif as designed in 1968 with L in the middle, prominent between 1&2 posts with West Yorkshire foundry logo underneath with the Y superimposed over the W and F also incorporated in bottom of the Y. Most of their work dried up by 1982 when Austin Rover took over Leyland and used their Beans Industries plant. The West YorkshireFoundry were taken over by Eisenwerk Bruhl in 1986, who also purchased Beans Industries in 1995 with the casting business at Beans to later become Ferrotech. Some heads were green or black unlike all the other A plus small bore yellow heads. No extra lugs on 3 middle front head studs as an early head pre 1981/2.

CAM4810 between 2&3 rocker posts with 3 strengthening lugs on 3 middle front studs with a B in a circle between 4th rocker post and end of head by the 8th valve was from Beans engineering cast with reference numbers either way up in same locations as they are only inset plates and they had a plug in rocker feed oil way rather than rivet. With the Beans emblem at the 8th valve they were all drilled for heater valve and by pass hose but for the Metro had a plug in the by pass hole and blanking plate for heater valve. Few Metro type less heater valve and by pass holes but i have one with D8N actually lead free, which might have been modified post factory build.

CAM4810 between 2&3 rocker correct way up but with letters BIL (Beans Industries Ltd) cast correct way up by end of 4th rocker post above 8th valve instead of the original Beans logos. Picture on left-Mini with heater valve and by pass holes drilled. Picture on the right where it is not drilled for Metro use and no by pass hose started late1988 to early 1989 and had a rivet rather than a plug fitted for the rocker oil feed gallery but not necessarily lead free. Only 1 out of 7 in my collection was Mini and only one Metro with lead free inserts which had 9H9 N by thermostat. Mini head above left with BIL was from a Mini City E 1985 and Mayfair 1986. These heads with BIL probably were the outcome of another set of tooling before Leyland being broken up in 1988 and a management team buying out Beans at the time.

Beans industries emblem on the left followed by 2 of the other stampings found on their heads and ND on the end of the cylinder head by thermostat cover indicating lead free.

N/D upside down just about readable behind thermostat and the screw holding the plate on for casting looks like a sunburst which denotes this N D head as being lead free from Rover

CAM4810 upside down between 1&2 rocker posts with 3 strengthening lugs on 3 middle front studs and a B in a circle between 3&4 rocker posts from Beans engineering usually had N/D with the visible plate screw looking like a sunburst behind the thermostat housing, denoting unleaded seats fitted. Some Minis after 1986 were unleaded to special order according to parts lists and different valves used on hardened seats, but all were definitely using lead free top grade seat inserts from Oct 1989. Rivet in the oil way for rocker feed rather than a plug for all these later heads. Out of my 16 heads only 2 were mini at time of this article and were made until 1991

Mini had a by-pass hose facility but Metro and Allegro were not always drilled for the by pass tube. The remote heater valve was fitted to Mini from 1989 and the last heads were not drilled out for heater valves, just a large detent for the water gallery.

Note 6. CAM4004-1.0625” inlet and round port

Has the extra air holes by spark plugs for anti pollution exhaust ports for countries like Australia and fitted around 1976-8. See Note 17 for a front view of the air ports. The casting number usually starts with an “E” reading ECAM4004 and is sideways by the 8th valve between 4th rocker post and end of head. Painted black they usually had single groove valves so technically just before A plus yellow heads

Note 7. 12A185. 1.156”inlet valve and square inlet ports

Beware this small bore 9 stud head uses the same 12A185 number as the cooper S large bore head 12A185/AEA626 but this is a small bore early 1961 first generation 997 Cooper with double valve springs, a 9 stud head usually on a 12A204 engine block with MOWOG above 12A185 in centre and between 3&4 rocker posts the Wellingborough emblem”W in a rhombus triangle shape” but it also made its way on a few other early 1100cc such as MG. Some early 948cc Midgets in the USA reported also having this head fitted hence maybe the two combustion chamber sizes found. It had square inlet port with recessed back manifold face being an early head and probably originally cast at the same time as the large bore head at the foundry in Wellingborough when Eddie Maher, Harry Weslake and Daniel Richmond were trying to develop BMC engines suitable for Formula Junior and then Formula 3 from 1964 for John Cooper inline engine single seat race cars in tandem with what BMC might require which ended up as part of the 1071cc and then 970cc S engines development program. See Note11 for the large bore type with 12A185 cast in centre plus AEA626 between 1st and 2nd rocker posts and Weslake emblem between 3&4 rocker posts known as the yellow head which is a pre runner to the AEG163 with bronze guides and EN214N 1.401 inlet and 1.22”exhaust valves which were shorter than the 12G940 casting valves, whereas the 12G 940 in all its guises used cast iron guides as standard.

Note 8. 12G202. 1.156”inlet valve with square inlet ports

MOWOG above 12G202 between 2&3 rocker posts and W upside down between 3&4 rocker posts. With recessed manifold back face, this from Morris Minor 1000 with 1098cc engine

Small bore head started with a recessed back manifold face from 1961 on the Morris 1100 being built at Cowley, 2nd generation 997 Cooper, Morris 1100 and Morris minor 1962-71, MG midget /Sprite 1962-64 — Austin 1100 from 1963-74 and A40 farina both being built at Longbridge with its own power unit from 1963-67, plus a few A35 vans to 1962 and A35 estates to 1968, Allegro 1973-1980, Mini special editions 1979/80 and Mini Clubman Estate manual 1976 to 1980. Spain replaced 1100 with 998 in 1974. Over 4,000 a week were cast at times and the total made was well over 1 million from the records that I could accumulate from cars and parts sales . Below is the earlier recessed or sculptured type manifold face which was phased out from 1967 on. NOTE- the very visible square inlet ports

All 12G202 heads had a square inlet ports starting in shape about ½”in and early types had recessed back face for manifolds and later 1967/8 on had flat back faces for manifolds. Heads less a by pass hose tube are probably Allegro 1973 on. Below is the later type Flat back manifold face that started with the 12G940 1966 and gradually phased in on other heads thereafter.

Produced in such huge volumes for so many variants most are as follows and all are interchangeable. Nothing rare or different in performance.

12G202 number cast between 1&2 rocker posts above 2&3 valves, MOWOG in centre between 2&3 rocker posts 23453 between 3&4 rocker posts with recessed back manifold face. Early circlip type cotters and valves

12G202SM less the Wellingborough Foundry emblem so probably a Longbridge head

12G202SM between 3&4 rocker posts with nothing else, or Wellingborough motif between 2&3 rocker posts (can look like 2G202SM on heads cast with MOWOG, all with early valves and circlips on cotters. Recessed manifold back on both types

Probably from Morris Engines Coventry not having W logo from Wellingborough Foundry

MOWOG above 12G202 cast upside down between 2&3 rocker posts and Wellingborough motif upside down between 3&4 posts, with flat back manifold face and majority with early valves with clips.

MOWOG above 12G202 cast between 2&3 rocker posts, Wellingborough motif upside down between 3&4 posts with recessed or flat back manifold face, but still with early valves and circlip cotters. Mainly off Morris Minor. Also pictured at beginning of title Note 8- 12G202

12G202 central markings upside down if looking from front of head with spark plugs facing you, no other relevant markings from Longbridge. Note lugs at back of 3 central front studs

12G202 cast upside down between 2&3 rocker posts with no other markings with extra 3 machined head stud lugs and flat back manifold face, some with W,Z or M by No1 valve. No MOWOG or Beans symbol .

12G202 cast upside down between 2&3 rocker posts with but with the Beans motif by the 8th valve and usually X or Z by No 1 valve with extra 3 machined head stud lugs and flat back manifold face and late valves.

12G202 cast sideways by number 8 valve beside 4th rocker post and no other markings with flat back manifold face with extra 3 machined head stud lugs, late head and some castings look like 12G20 as the last number 2 is lost in push rod hole

12G202 at back of thermostat housing with Wellingborough motif

12G202 on ridge behind thermostat housing with small Wellingborough symbol beside it and flat manifold face, extra 3 head lugs, rest of top face pretty bare, last type of casting made at Wellingborough foundry and also sold as last replacement stock for spares of part number 28G193.

Note 9. 12G201. 1.156? inlet valve with square inlet ports

BL in rectangle above 12G201 cast between 2&3 rocker posts, Fitted to AUTHI 1100 ADO16 from 1967. Same as 12G202 but different volume combustion chamber. These had recessed manifold faces and good core centralising when cast, making them ideal for modifying. A few seemed to end up on Italian 1100 variants where Mini Spares imported many for sale in England.

Note 10. 12G206 1.156? inlet valve with square inlet ports

Keith Calver says- The 12G295 invariably has bigger intake ports and very shallow short side radius. For most road applications the ports are too big as standard – It does not need port work doing, just sorting out the valve seat shape and valve throat area. The inlet valve throats often have very, very thin seats so the valves seem to be barely hanging on. Also generally the throat has what appears to be an insert fitted because the underside is square stepped in shape like a shallow insert, they are cast like this. The 295 was produced for Group 1 race/rally homologation in mind at a time where big was beautiful. Keith Calver is still amazed at some of the valve sizes they crammed into them. The 206 is a much better head for road use – including those with a sporty camshaft. Far less prone to cracking as well.

Often described with the wrong description and wrong inlet valve sizes as an alternative to 12G295. Even our catalogue had inlet valve size wrong with a typing error from the late 90’s on hard copy which many have copied without research but I can confirm the following. The Inlet valves were original 1098cc size at 1.156?. Cast with MOWOG above 12G206 between 2&3 rocker posts, it has a recessed back and Wellingborough symbol between 3&4 rocker posts. Has square inlet ports and no locating ring recess and same 12G202 inlet valve size but often increased by .060” to the 1.218 inlet for either valve seat repairs or performance. The better flowing combustion chamber shape is 28.4cc but smaller and deeper at around 0.450” whereas the 12G295 is larger and shallower at around 0.430”deep, usually 20-25 thou difference. Although listed as part number 28G191 by BMC in AKD3509 parts list for very early 998 Cooper with low 8.3 CR, and a few 9-1CR- (I can only ever remember seeing the raised D shape pistons for 9-1 CR with 12G295 castings back in the 60’s}. Mainly fitted to inline 1098cc 10CG engine Sprite/Midget 1962-4, pre 12G295 fitment, plus a few found on A40, Morris Minor with 1098 engines but probably had Compression Ratio modified aftermarket.

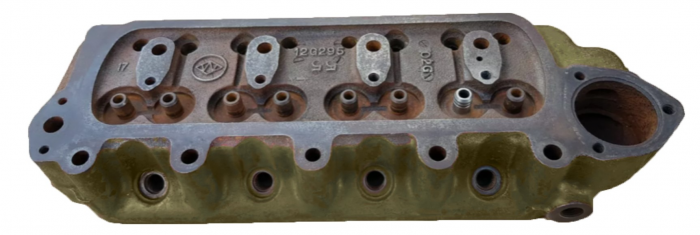

Note 11. 12G295 1.218? inlet valve 1963on

(A)Early head with recessed back, Mowog is much lower than push rod holes

A) Even though all Coopers were assembled at Longbridge the first heads had Mowog above 12G295 cast in the middle between the 2&3 rocker posts, below push rod holes. Note- Wellingborough symbol between 3&4 rocker post on this early head which has a recessed back manifold face.

(B)This is the 12G295 with flat or recessed manifold back but see Notes A and B

B)Mowog above 12G295 in middle but cast higher with M just touching push rod holes, Wellingborough symbol between 3&4 rocker posts and 13 under 12G295 often had a flat back manifold face, but not all. 14 and higher numbers were usually flat back

A later casting had the 12G295 casting number lower in the centre and mostly with 55 upside down but without Mowog and only the Wellingborough symbol between 3&4 rocker posts plus the flat back manifold face. All have large inlet ports with recess holes for locating ring 12G297 to mount the inlet manifold. Read KC view above on 12G206 for the 12G295 differences. Some 295 heads from records now lost showed they were cast in North works Longbridge. First found on MG1100 from Oct 1962, plus Riley Kestrel 1100, Wolseley 1100 and Vanden Plas 1100. Fitted to 1964-66 MG & Sprite with 10CC engine number and all 998 Cooper 1963-69 apart from early cars 9FA SA H 101 -1035 and L101-1581 according to the parts list AKD3509 which used 12G206 of which many went to the USA on MG’s.

Note 12. 12A185/AEA626. 35.6mm(1.401?) inlet 31mm (1.22?)exhaust

If you look at first rocker post to below No1 push rod hole there is no raised bridge casting going to head gasket seating area as per other heads because the oil feed gallery to rockers was in the head gasket face shown on R/H half head picture. You can just see oil feed from top left hole. Later heads such as the AEG163 and AEG305 remedied this. This 11 stud large bore head has MOWOG above 12A185 between 2&3 rocker posts and AEA626 between 1&2 rocker posts and note Wellingborough symbol upside down between 3&4 rocker posts. Known as yellow head with bronze valve guides and EN214N valves. Pre runner to AEG163 this head is often misidentified as there was a 9 stud small bore head with same part number 12A185 for 997 Cooper but less the AEA626 (see Note 6). Had the recessed back and known as the Yellow head was fitted to the first 1071 Cooper S 1963. All these heads I have seen have the rocker feed oil gulley on the head gasket face, which is not on AEG163 or AEG305 showing it was a later version. This head was also fitted to the 948cc inline A series blocks and other racing conversions back in early 1960’s. Bronze guides and EN214N valves.

Note13. AEG305 35.6mm(1.401?)inlet with 31m(1.22?) exhaust

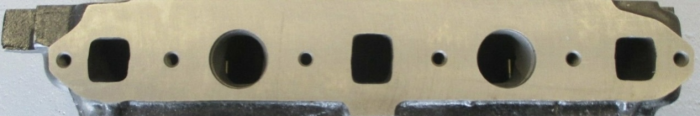

Manifold face is typical of a recessed or sculptured type early face

Rare, maybe an early experimental 1964 large bore head with AEG305 between 6&7 push rod holes and MOWOG between 2&3 push rod holes both cast upside down. Bronze guides and EN214N valves with 11 studs and recessed back. I have seen quite a few examples but my good friend Steve Harris still has an original. Probably made for 970cc bored to 997cc for Formula 3 use on Cooper A series engined single seater racers and often the heater tap hole was not drilled as per photo above and a water elbow added on side of the head which helped to cool the 4th chamber and port. I have also seen this head on an early Cooper 1275cc engine less heater tap drillings. Downton played with this head and AEG163 on 997cc Cooper and undercut the block to accept larger exhaust valves which he later reduced in size for longevity on his 12G940 head design.

Note 14. AEG163 35.6mm(1.401?)inlet with 31mm(1.22?) exhaust 1.22”

A-Most common AEG163 with MOWOG above from a 1275 Mk1 Cooper S and the W for Wellingborough foundry in a rhombus diamond shape on ledge at back of thermostate

B-Off an original 1070 with AEG163 between 6&7 push rod holes and MOWOG between 2&3 push rod holes all upside down with Wellingborough logo in middle replace by 24J on some

A-MOWOG above AEG163 between 6&7 push rod holes, with W for Wellingborough on a ridge behind flat surface of thermostat housing area. B-MOWOG between 2&3 push rod holes, AEG163 between 6&7 push rod holes with W for Wellingborough emblem between 5&6 push rod holes and all upside down from the front view on early heads, with W being replaced by 24J and the W going on a ridge behind the flat surface of the thermostat housing area on later batches. EN21 4N valves, steel caps and bronze guides this large bore 11 stud head was fitted to MK1 and a few MK2 Cooper S and were known to be prone to cracking with the large valves and stud breakage on weak posts for the rocker studs. Note the brass plugs in photo above which were above the inlet/outlet alignment cores. Most AEG163 heads had full recessed back face for manifolds and later 1275 heads had flat back down to below port holes and then recessed. Originally known as blue or brown head and introduced to Cooper S 1071 from Oct 1963 and 970/1275 when released until phased out by 12G1805 early 1968. The 12A185/AEA626 was known as the yellow head.

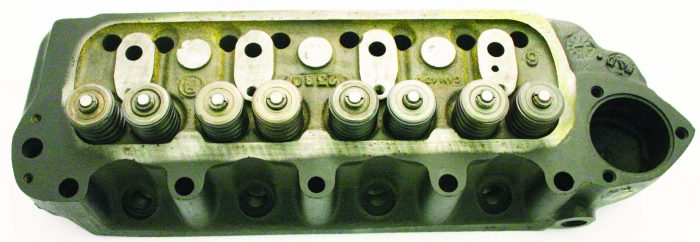

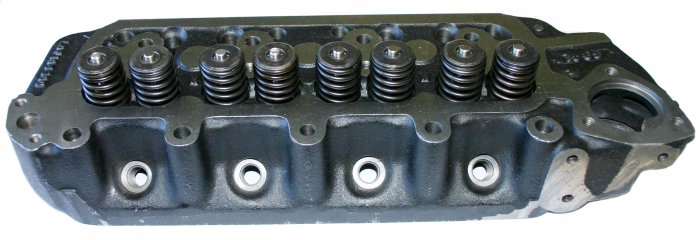

Note 15. 12G940 1.3125?inlet 1.156?exhaust

Full flat face on Thermostat end from Wellingborough Foundry with W emblem between 6&7 push rod holes and MOWOG above 12G940 between 2&3 rocker posts

One of the Pre A Plus later flat face types from Longbridge and cut out by thermostat hole. The 12G940 cast between 4&5 push rod holes often looks like 2G94 or 12g94 on some heads

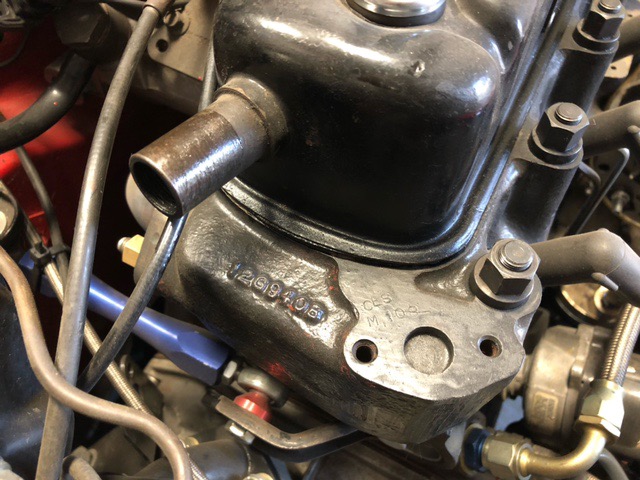

Early 12G940 Mowog castings pre 1981 were first used on MG Midget and Sprite from 1966 when they were sought after by all engine tuners as they offered greater potential for modification to increase performance and reliability compared to the AEG163 head. These early 12G940 known as flat face heads had well aligned cores from their new castings and smaller 33/29mm valves with more metal which was an engine tuners delight to put their own shape valve throats and size valves in. Some had other numbers punched on them about 1/8” tall on the area behind the thermostat which only denoted what vehicles they were going to be fitted on once assembled. 12G938 and 12G293 from 1966-74 are two and from 1968-74 the 12G1805 see Note 16 indicating the larger inlet valves and 2 extra stud holes. 12G938 stamped on flat area behind hole for thermostat showed it was destined for the Midget and Sprite 1275cc with double valve springs fitment and had good centralised cores for head modifications. (Fig A) below

Most UK heads have 12G940 in centre and early heads with an X above, or MOWOG above or below the 12G940 number and usually with a W in rhombus diamond shape for the Wellingborough Foundry trade mark between 3 & 4 rocker posts. All had the flat machined back manifold face and early flat top face type as above and did not have the extra strength lugs on front 3 head studs. The only 12G940 casting oddities I have seen are, where 12G940 is cast behind the thermostat (Fig B above) about 1978-80, pre A plus with the extra lugs which mainly seemed destined for CKD kit cars sent to Belgium, Innocenti and probably for the Allegro which were built there, a Longbridge head with no other markings. Apart from the 12G1316 smog port head, see Note17 the only other 940 derivative is the good head from Authi Spain, it had 2G93 above the NMQ-BMC in the centre, see Note16 Pre A plus heads from Uk cars -Mini 1275GT 1969-80, Austin 1300 1967-74, Morris 1300 1967-73, MG1300, VP1300, Wolseley1300, Riley Kestrel 1967-68, Austin Allegro1973-80, Morris Marina 1971-80 and Midget 1966 on all with heater valve drilled and by pass hose.

A PLUS versions Longbridge production 33mm inlet. A repainted sample of an early A plus where 12G940 cast number is still proud to about 1988 is below, plus an identical head in original colour.

Early A plus heads still have the 12G940 visible and mostly without lead free inserts

A plus heads from Longbridge 1980 on, have less material in them giving them thinner wall sections where the water jackets were enlarged and improved, all 12G940 heads are interchangeable but check drilling differences for your own requirements. Metros, Maestro, Cooper RSP, Ital or Allegro, did not have a by- pass hose facility but RSP unleaded had heater tap drilled. Morris Ital 1980-82 and Marina 1.3 did have by a pass hose. All A plus had the extra machined flat lugs around the back of the 3 front centre stud holes, plus raised ribs from the rocker cover gasket surface out to the thermostat and also an area behind it, plus one to the heater tap location and one from 4th rocker post. The first A plus as per the picture above still had the 12G940 very visible and raised but the next generation as per the Turbo head pictured below in original A plus head colour are machined down to the surface of the rocker cover gasket face which takes away nearly all the original 12G940 casting number but more metal in the head face which apparently helped cooling still leaving the head with the original depth of 2.750?which in turn makes them useful if a larger combustion chamber size is required. Introduction of a noticeable rivet in the back of the thermostat end to close off the drilling hole for oil way to rockers. Single collet valve stems were being phased out by 1983 and replaced by triple groove valves with a new top cap and twin groove collets with a 14 degree angle as opposed to 10 degrees probably instigated by Lotus for use on the Metro Turbo 1982-90 enabling valves to turn/spin more freely.

The A Plus Turbo head shown above had a T punched on the area by the non drilled heater tap location and used 8mm wider sodium filled valves for better cooling, noticeable on valves 4,5,8 with different top caps. Note, the extra strengthening ribs machined flat where Pre A plus just had lumps and extra metal on top to cater for the larger internal water jackets and the top face machined down to original 2.75? depth making the 12G940 nearly illegible and leading up to the start of Lead free heads 1989. Fitted to MG Metro Turbo 1982-90 and ERA Turbo 1989-90. So many core changes and casting shapes have been produced that with the later A plus varieties included there must be at least ten different types of 12G940. Most A plus heads were cast at Beans Industries Tipton who then became Bruhl which later became Ferrotech and machined at Longbridge.

Note16. 2G93 1.3125? or 1.401?inlet 1.156 exhaust 9 or 11 stud

AUTHI Spanish version of 12G940 head for 1275cc models but marked 2G93

Made made by Nueva Montana Quijano from Pamplona, in Spain for Authi 1275cc models it was good for modifications. I have seen 9 stud versions with 33mm inlet on mini 1275C/1275GT and 11 stud with 35.6mm size inlet valves on Mini Cooper 1300 models and none indicating that the 2G93 could be 12G93 or 2G93 something, which might well have been the part number but My Authi microfiche shows only replacement part numbers.

Note17. 12G1316 1.3125?inlet 1.156?exhaust

All based on a 12G940 Pre A Plus, the USA anti- smog casting has either either MOWOG above 12G1316 or just 12G1316. The air holes are on the pillars beside the spark plug hole and can be blocked off, originally for non-air pollution countries. I have seen at least 4 types of these, even where the pillars are not drilled on a new replacement head sold as part number 38G431. Most have the Wellingborough W symbol and very good cores for modifying.

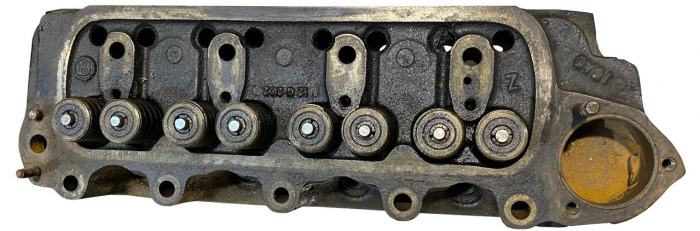

12G1805 with the S stamped above the thermostat area but to small at this angle to see but check below. Flat front type typical of all early Wellingborough 12G940 heads

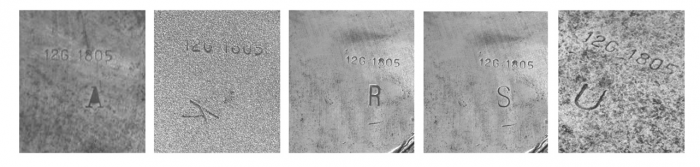

All 12G1805 UK heads had the following symbols below them, A,K,R,S,U plus rumours of an H which I have yet to quantify from original vehicles

12G940 in centre sometimes with X above it and Wellingborough W symbol with 12G1805 and another larger letter usually A,K, R, S, or U stamped by the thermostat back face, these had 11 stud holes which originally denoted larger 1.401” inlet valves. The 1805 casting cores were not always consistent and any 12G 940 castings can be converted to have either the extra stud holes or the larger inlet valves fitted aftermarket. If you have an 11 stud “S” head without any 12G1805 markings as described they might be from Blackheath, Gauteng plant in South Africa as I imported over a hundred at least. Any A plus head is an imposter of the 12G1805 and probably converted from Note 17 the next listed head. The 12G 1805 was fitted to MG1300 and Riley 1300MK2 1968-69(not Kestrel), Austin or Morris 1300GT Cooper S Mk2 from early1968 and all Cooper S Mk3 1970-71

Note 19. 12G940 Non S 1.401?inlet 1.156?exhaust with 9 head stud holes.

original large inlet valve head A plus 9 stud fixing and above with new valves

Same as other 12G940 A plus castings, with only 9 head stud fixing holes but fitted with the large 1.401 inlet valve. Many of these have now found their way on to other cars and drilled with the 2 extra stud holes claiming to be for Cooper S. No by pass hose. These heads but less heater tap came from Vanden Plas Metro manual 1984-89,Maestro 83-86, Montego 1984-89, MG Metro 82-89 and GTA 89-90, Morris Ital 82-84 but 80-82 earlier Ital heads were small valve.

Note 20. 12G940B 1.3125?inlet 1.156?exhaust

From 1991 the SPI head had a new number 12B940B also cast on the end of head as shown with the B sometimes looking like an 8. Note heater tap hole not drilled. ALL LEAD FREE

12G940B cast between 4&5 push rod holes (but often the B is lost in the push rod hole) and also 12G940B was cast in the heater tap end of the new casting introduced in 1991 for the SPI single point injection cars with no drilling for heater tap, no temperature transmitter hole or by pass hose, all are lead free and it has a noticeable large rivet in the back of the thermostat end to close off the drilling hole for oil way to rockers. The pre runner to the MPI which like this is supposed to have the best cooling jackets to date but with less metal on the walls, – especially on the two end exhaust ports on the ‘outer’ walls when modifying. Has 3 small core plugs rather than brass plugs in head gasket face. This SPI head was also used on other variants and modified by the factory with by pass hose and temp transmitter hole for HIF38 carb fuelled cars where required. The first 1275cc lead free head recognisable by number from the factory. Also found on Mini with HIF38 carb, Mini SPI, one claimed to be on RSP Cooper but unlikely as standard.

Note 21. LDF105380 1.3125?inlet 1.156?exhaust

The last A series casting made and looks different on the front face as it has 3 bolt locating holes for an alternator where the temp transmitter used to be and they are meant to have the best cooling characteristics for the Mini. There is no 12G940 marking on this head but just the number on the end. These can be used on any 1275 Mini but the heater tap holes, temp transmitter hole and by pass hose will have to be drilled and thermostat seating area machined deeper to accept thermostat or by using a special gasket PEQ100650SPACER. The temperature transmitter hole which is missing can be drilled out and threaded in the location of the bottom alternator bracket hole.Mini Spares has sold many of these as performance heads with the areas mentioned converted.

Note 22. C-AHT347 ALLOY HEAD 1.406?inlet 1.161?exhaust

Professional Photographer

Based on the last 12G1805 samples of Leyland 12G940 flat faced modified casting but made in alloy to aid heat dispersion, weighing only 5.7kg with fully modified ports, bronze guides with safety clips, plus EN214N race quality valves. 21.3cc to 21.5cc combustion chambers, the same as all original large bore heads. Beryllium valve seats spaced to avoid cracking. Heads are heat treated and pressure tested before and after machining giving a top performance product. Also available with larger 37mm inlet and 31mm exhaust valves spaced further apart for strength but using colsibro guides and titanium top caps for one the best performance heads available at exceptional value, either C-AHT347RACE and C-AHT348RACE.

Blanking and drilling options for water ways on original heads. If you do not require heater take off valve use blanking plate 2A180 and gasket 88G221. Options for by-pass hose is blanking cap CAM4126 or remove by-pass hose adaptor and fit blanking plug 88G619. For single point injection only – blank water temp gauge sender unit hole off with 5/8?UNF threaded plug (part number 5/8UNF). To change post-1992 head (including MPI variants) to pre-1992 fitment – Drill 9/16?(14.5mm) hole through counter-bored heater take-off hole (1/4UNF heater tap retaining stud holes are already in place) or remove blanking plate if fitted. For by-pass hose, either drill/tap 5/8? UNS (16TPi) port in required place and fit by-pass hose adaptor 12A2075, or drill/tap 5/8?UNF and fit adaptor tube 12H1405, or blank water pump port off with blanking cap CAM 4126 and either drill 1 to 6 of 1/8?/3mm holes around thermostat periphery or fit blanking sleeve 11G176 (really not good for road use – recommend thermostat is fitted). For water temp gauge sender unit either drill/tap port out to 5/8?UNF thread or remove 5/8?UNF socket headed grub screw if fitted.

It was rumoured and might well be a fact that Daniel Richmond’s Downton Engineering designed the 12A185 and AEG305 for the Cooper S and 12G295 for BMC and almost certainly the 12G940 casting that replaced the AEG163 casting for which he received royalty payments but that all finished within the shake up of BMC to Leyland in late 1969. Just to add to the confusion was the Weslake logo (a large W in a rhombus diamond) placed in a circle found on many 12G295 heads and others, many assumed was for Weslake design and patents. Cylinder heads were also cast at Wellingborough Foundry, Morris Engines ,Courthouse Green, Coventry and at Longbridge North Works originally and maybe the East works where assembly took place. Also Birmid Qualcast now part of Midland Motor Cylinder Company. Beans Industries, Tipton also known as Beans Engineering took over some of Wellingborough foundry work and all of it finally, on Wellingborough’s closure in 1981.

803cc to 1098cc engine head swaps. Leyland found the stronger 998 A plus engine with its new block/piston, high compression set up was apparently only 1 bhp down against the 1098cc engine and more economical which then started a gradual phasing out of the 1100 longer stroke engine on some vehicles. The figures have been disputed but the question still arises on forums whether you can fit 998 heads with 1.0625?inlet on 1098 engines and vice a versa with the larger 1.156? inlet head to a 1000cc. The 1098cc head made for the larger valve has extra flow area around the inlet valve whereas just putting a larger valve in the small valve head creates shrouding and no power increase. The larger valve in the correct head does help to give higher revs mid range and a few BHP more on 998. Putting the small valve head on 1100cc block loses a few BHP and revs are diminished. In Laymans terms it feels about the same to the equivalent of power loss or gain with having new or worn pistons so is noticeable. Both these heads can however be greatly improved by removing metal around the large valve guide seats especially the exhaust and either type worked by a specialist can give great results. So basically, do not put a smaller valve inlet head on a larger valve head engine unless desperate. You can always put a larger valve small bore head on a small bore head engine but carburation, timing, or a rolling road set up will be required. The compression ratio will also need to be checked and the head shaved but A Plus 998 heads do not need as much material removed as the earlier 998 which had a lower compression. 24.2cc seems to be used on most Mini Spares modified heads but 24.5-25.5cc combustion chamber is ok for use with flat pistons.

2A629 was the original Harry Weslake port design that was more or less identical on 12A1455,CAM4004 and CAM4180. 12G201,12G202 and 12A185 used the next size up 1.156? inlet valves and BMC had to de shroud the combustion chamber in that area to make it flow but they look the same, but with an increase in combustion chamber capacity. 12G295 had a different shape chamber as per Daniel Richmond’s design which he also closely followed on his Stage One Downton modified cylinder head kits for Special Tuning Abingdon to suit the Mini and 1100. 12G206 had fairly similar design chamber shape with as the 12G295 but with 1.156? inlet whereas the 12G295 had the largest inlet valves 1.218? of all the small bore heads. 12G940 used the same design by Daniel Richmond but a larger combustion chamber with less cubic capacity and different larger size valves.

When modifying cylinder heads Keith Calver and other head modifiers have passed on the following knowledge-Generally, what makes a head casting better than another one for modifying is being able to identify the more centralised cores, and certain other beneficial offsets. Smaller-valve heads on the 12G940 (those with 33,3mm inlet valves) especially pre A plus are better for modifying as there is more material in the valve throat to achieve better shapes because they increased the A Plus head coolant jacket volume to improve cooling (more coolant volume). The result is thinner ‘wall’ sections meaning easier to go through in all the wrong areas. Coupled with some very wayward core shift during casting makes A plus heads less desirable to modify. 1991 on A+ castings are also from different tooling to the earlier A+ castings 1980-1991.But then much of all this depends on how much material you remove to achieve the performance you are looking for or deem necessary, to achieve your preferred port shapes. Having spent a great deal of time modifying, flow testing and then dyno testing head modification types, much less material is taken out these days so they have fewer problems going through the walls. Though race heads can still be a nervous ordeal depending on the casting.

BMC PART NUMBERS FOR CASTINGS

| Casting number | Part Number |

|---|

| 2A629 | 2A613 |

| 12A1456 | 12A1455 |

| 12A185 | 28G141 |

| 12G202 | 28G193 |

| 12G206 | 28G191 |

| 12G295 | 28G222 |

| AEG163 | 38G360 |

| 12G940 | 38G399 |

| 12G940 35mm inlet | CAM6633 |

| 12G940 Turbo | CAM6979 |

| 12G1316 | 38G431 also a 12G939 on 940 casting |

| 12G940B unleaded | TAM2153 |

Foundries and brief history of owners.

Many of the foundries were sold off and then sold on again as the car industry diluted its requirements with mergers, rationalisation and cost cutting exercises to finally suffer through recessions and shrinking market. Cylinder Head Manufacturers. Originally Morris Motors plus Wellingborough Foundries for Morris cars. Longbridge, GKN and Beans for Austin cars. Austin and Morris amalgamated in 1952 and later on started joining forces in production.

Longbridge North works foundry produced head castings until the move to East Works known as Hacket Coften new engine plant in about 1968-9.

1960 Beans became part of part of BL producing castings and blocks for commercial and coaches and in 1975 became Beans engineering.

1988 Leyland Group was privatised by the conservative government and Beans Industries was acquired by its management team. After this Beans acquired Reliant in 1992. Mini 998cc cylinder head production ceased for assembly line 1991/2.

1995 Reliant failed which forced Beans into receivership and the Tipton, Staffordshire, West Midlands factory was purchased by German company Eisenwerk Bruhl in 1997 trading as Bruhl UK which had invested heavily making it one of the most modern up to date and efficient plants in Europe supplying Rover cylinder heads and blocks but the debts incurred finally forced them to sell and the business then had another management buy out and became known as Ferrotech who carried on as main head supplier and cast its last part September 2005 after the collapse of Rover.

CBS - C &B Smith of Stewart Street Wolverhampton. In 1965 became part of GKN FORGINGS and CASTINGS, then in 1982 became Birmid Qualcast specialising in cylinder heads and general engineering. Birmid was sold to Sterling Metals to Blue circle industries, all part of Dartmouth Auto castings which is now Cornwall Holdings.

WYF. West Yorkshire Foundries. In 1964 they were supplying Jaguar and `Coventry Climax blocks with special blocks for racing. In 1966 they built a state of the art gravity die casting factory and supplied Rolls Royce, Aston Martin and Jaguar. In 1980 along with other BL closures such as MG Abingdon they laid off half of its workforce and was finally sold to Eisenwork Bruhl in 1986. 1992 it was acquired by VAW Motorcraft and Norse Hydro joined up with them in 2002 to be renamed as Hydro Aluminium Motorcast Ltd and many other names including the word Alloy before settling as VAW West Yorkshire Foundries.

Michael Edwardes joined BL in 1977 under a labour government and started closing down nearly a third of all plants, halving the workforce to try and stop the money losses and by 1982 when his contract was ended he resigned.

In the end it had annoyed Thatcher who had become prime minister in 1979 as she wanted to sell off more parts of the company whereas Edwardes always requested more funding but Rover with its new Metro in sight would limp on until 2004/5 which kept some foundries producing heads and blocks, a lifeline.

The Wellingborough Foundry was last used for producing A Plus 998cc heads for Metro and Mini until it closed in 1981. It was the major casting supplier for Morris in the 1960's to mid 70's for all heads and Longbridge for the ADO16 1300 power unit. Morris engines at Courthouse Green had produced many early MOWOG castings and owned Wellingborough Foundry but by 1965 Wellingborough alone had cast over a million A series heads.

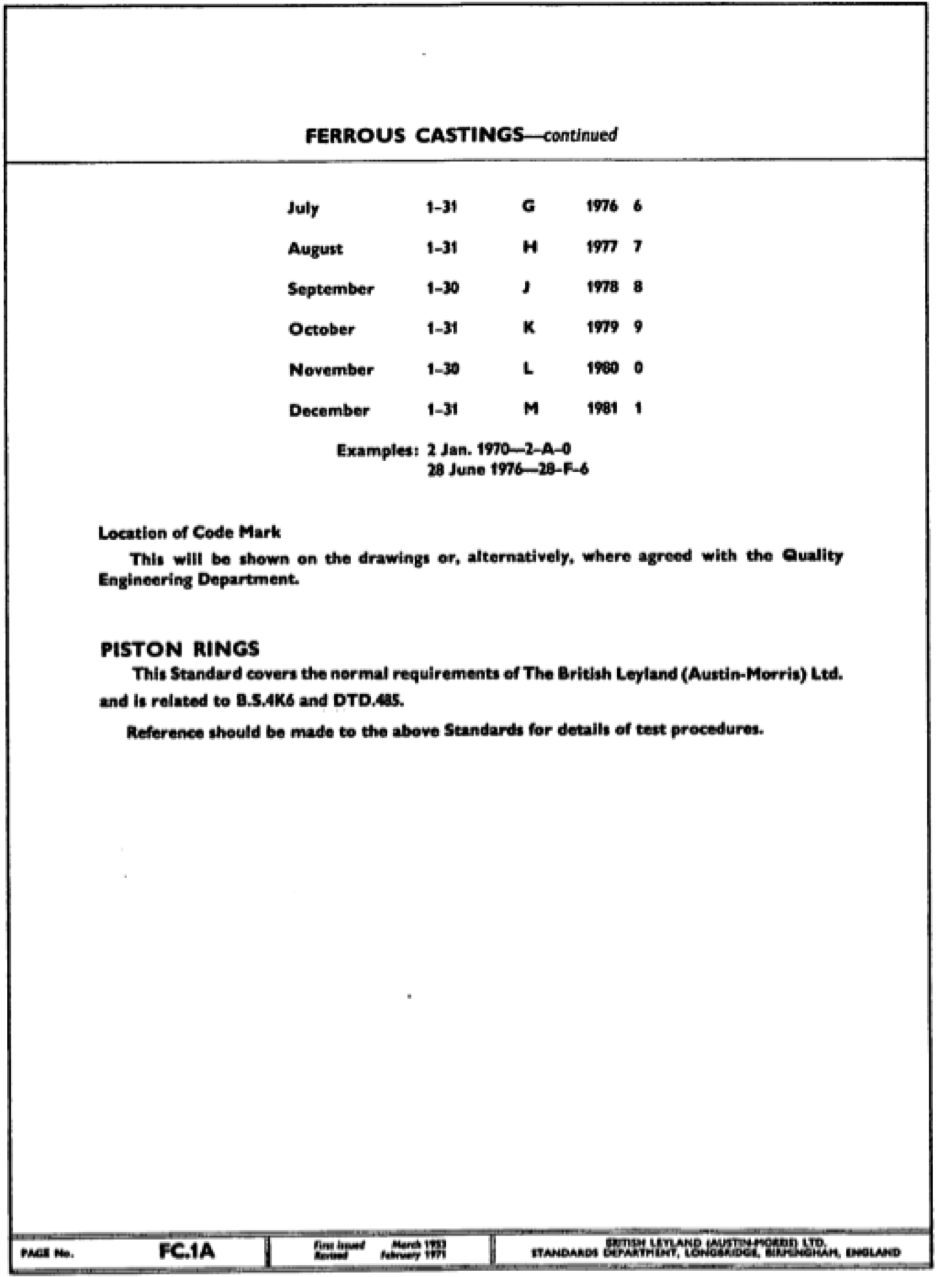

Date Standard for Ferrous Castings

First issued in 1953 for the introduction of US federal regulations on Motor Vehicle safety, castings became date stamped up until the 1980’s.

The only problem was that the last letter for the year was the same for 1953,1963, 1973, 1983. The first 1 or 2 numbers were the date and the single letter for the month. The letter I was not used for the month to same complications with the number 1. The last number being the year. They would have known whether it was 1950,1960,1970, by the vehicle part made or built in that decade. There were also some markings showing what shift or batch the items were made from, but they could appear before or after the main date information which can be confusing or hard to work out unless somebody can provide further proof or information which can be confusing or hard to work out unless somebody can provide further proof or information. Examples after BL explanation sheets.

Example= 21J8 is 21st September but year could be 1968 or 1978 Pre A Plus or 1988 for A Plus. 21DJ8 the D would indicate the batch or shift it was cast on so still dated as previous. The D shift number could also appear after the year such as 21J8D so you need to decipher the main date numbers and letters discarding the shift. Any head with the Wellingborough motif which are harder to date had to have been made before its closure May/June 1981 at the very latest and the final tooling was not moved to Beans at Titpton until after September 1981 but would imagine any tooling with the W for Wellingborough would have been erased. I have no record of what was made up to the dates shown as the transfer of work to Beans had started in 1980. Hopefully any ex employees of Wellingborough, Longbridge or any other foundries will provide any extra information to help us build up a record of the long lost records.